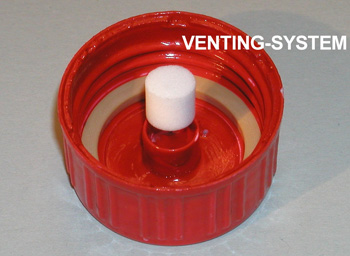

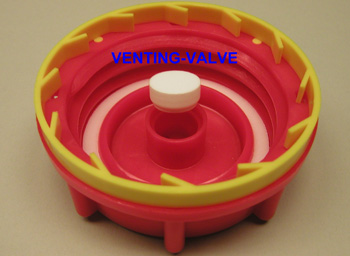

Notably, our valve systems boast a hydrophobic and oleophobic effect, preventing leakages even when the packaging is inverted.

Designed to ensure exceptional degasification rates, our Ventix Valves are crucial for handling hazardous substances like inorganic and organic peroxides, chlorine bleaching agents, and similar chemicals.